We specialize in creating customized inspection reports, developed based on your specific dimensional or technical requirements. Thanks to our expertise, we ensure accurate and comprehensive reports that meet the most detailed specifications. Each report, fully digital, is designed to optimize the monitoring of individual control parameters.

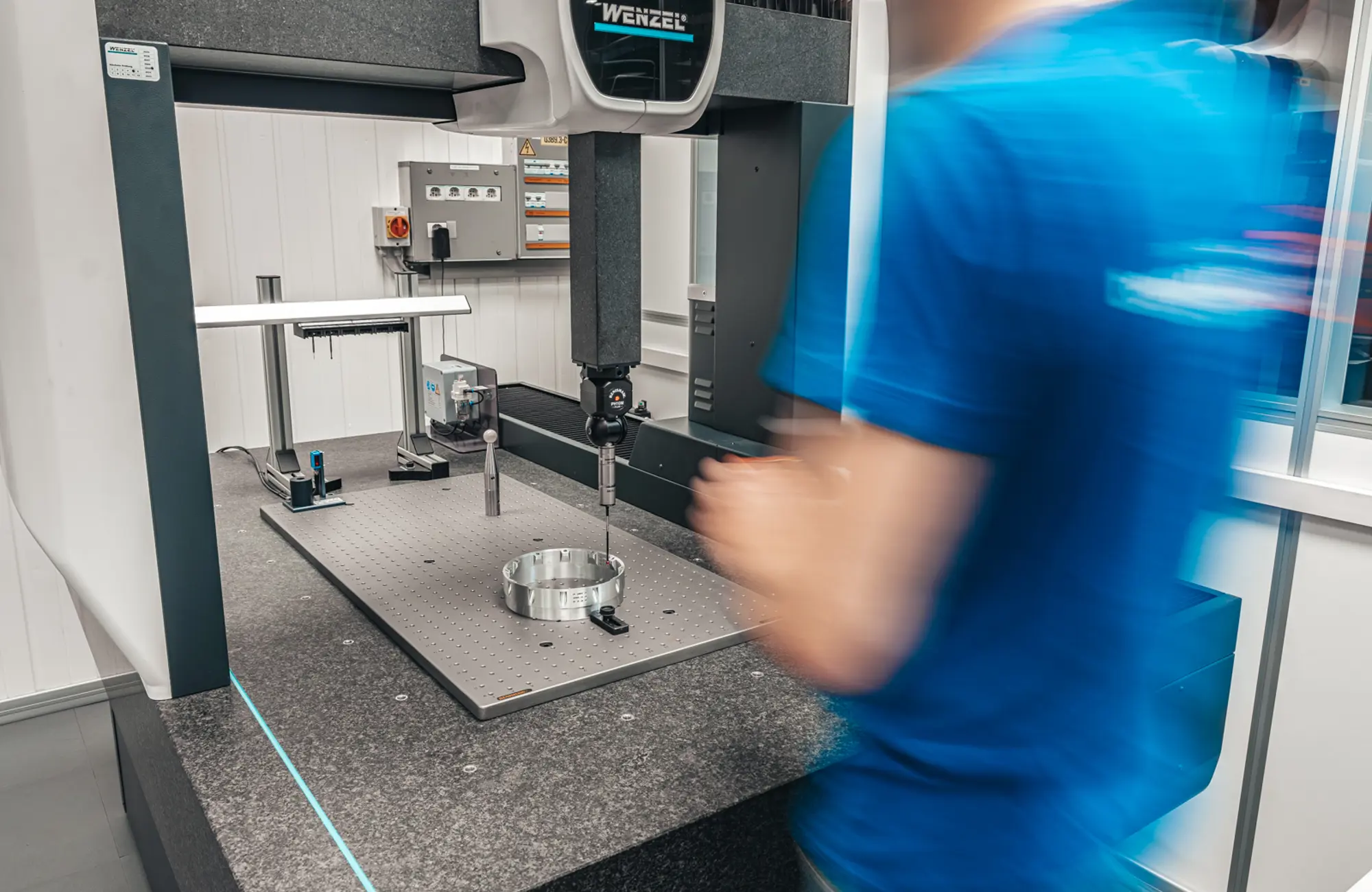

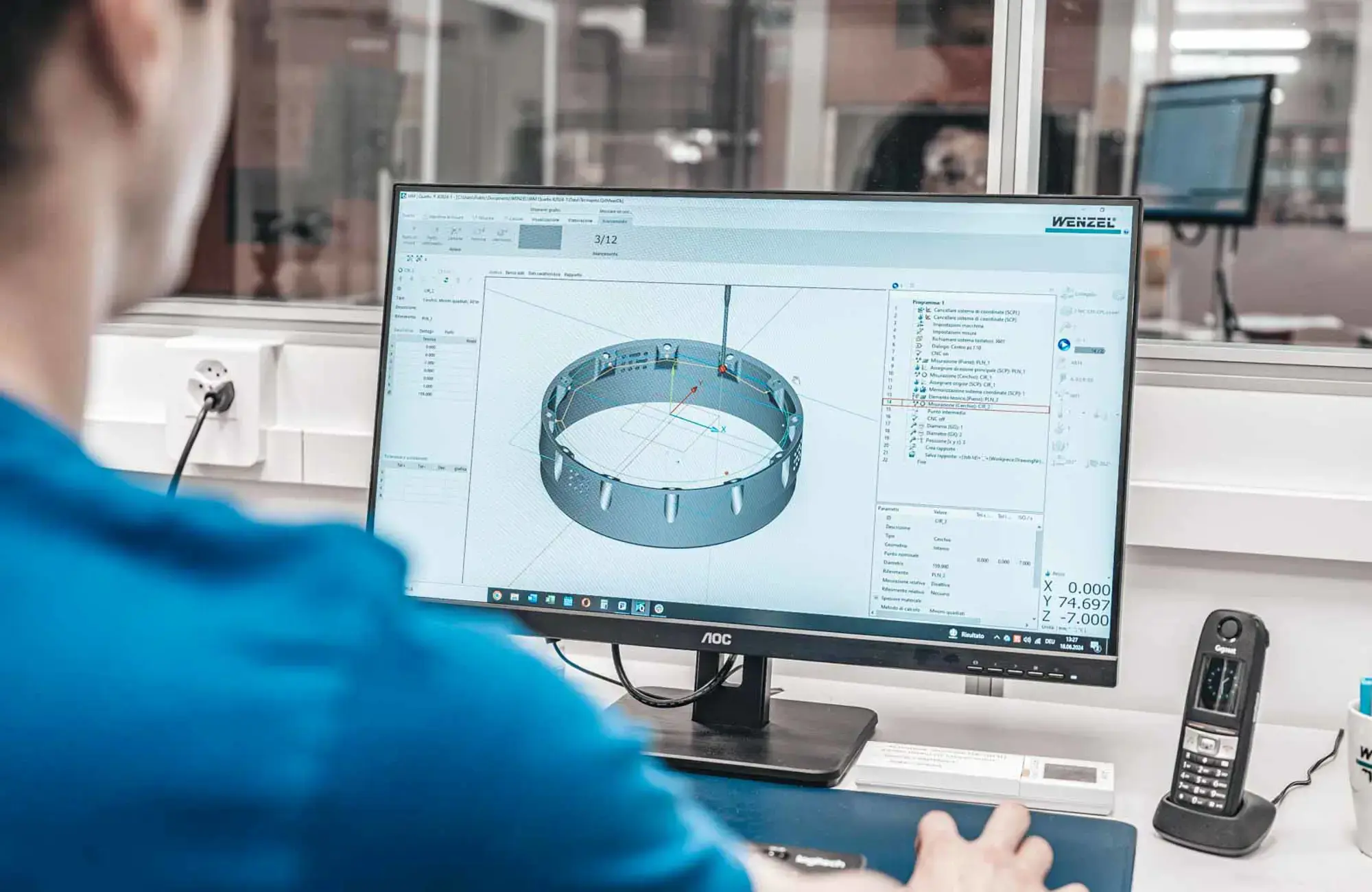

To ensure full compliance with your quality specifications, with precision tolerances that can reach up to 0.001mm (0.00004 inches), we perform precise dimensional checks of components both during production and at the end of the manufacturing process, using state-of-the-art metrological instruments.

In our control department, we have a dedicated area for metrological inspections, equipped with an advanced Wenzel 3D measurement system. This tool ensures the highest levels of precision and reliability in our measurements.

Thanks to the complete digitalization of our business processes, we can instantly access production data, offering the ability to trace the entire manufacturing journey of every product delivered.

Traceability is also ensured on supplied components. Using laser engraving technology, we can identify items via alphanumeric codes and/or QR codes.